Product Description

Our factory

Loading

FAQ:

Q1: How do you guarantee quality?

A: We take quality inspect records from raw material to finished product.

The former department bear 100% responsibility for next process to guarantee quality.

Q2: Can you produce if we have samples only?

A: Our technical ability is strong enough to deal with different types of spring.

Sample drawing and customers’ interests will be protected well.

Q3: Is it possible to have sample for quality testing?

A: Same or similar sample are available for free.

Q4: What is your MOQ?

A: For common material size, MOQ requires 30~50 pcs;

For special material size, Moq requires 3 ton or more;

Q5: What about the package of the product?

A:The goods will be packed according to your requirements and in well protection before delivery.

Q6: What is your terms of payment?

A: T/T, L/C at sight , Western Union.

Q7: What’s the delivery time ?

A: Most of parts are available in storage. For container delivery, 1 container can finish loading in 10 days.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 6 Month |

|---|---|

| Warranty: | 6 Month |

| Type: | Suspension |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there aftermarket axle spindle options available with enhanced durability or features?

Yes, there are aftermarket axle spindle options available that offer enhanced durability or additional features compared to the original equipment manufacturer (OEM) spindles. Here is a detailed explanation:

Aftermarket parts are manufactured by companies other than the vehicle’s original manufacturer. These companies often specialize in producing high-quality replacement parts that may offer improvements over the OEM components. When it comes to axle spindles, some aftermarket options are designed to provide enhanced durability or incorporate features that can benefit specific applications or driving conditions.

Here are a few examples of aftermarket axle spindle options with enhanced durability or features:

- Performance Spindles: Some aftermarket manufacturers offer performance-oriented axle spindles that are designed to handle higher loads and stress levels. These spindles are commonly used in applications where increased durability and strength are required, such as heavy-duty trucks, off-road vehicles, or vehicles used for towing. Performance spindles may be made of stronger materials or feature reinforced designs to withstand more demanding conditions.

- Upgraded Materials: Aftermarket axle spindles may be manufactured using advanced materials that offer improved strength and corrosion resistance compared to the original spindles. For example, spindles made from alloy steel or heat-treated steel alloys can provide enhanced durability and longevity, especially in harsh environments or applications subject to heavy loads.

- Improved Design and Engineering: Aftermarket manufacturers often analyze the weaknesses or limitations of OEM spindles and develop improved designs to address those issues. This may involve optimizing the geometry, reinforcing critical areas, or incorporating additional features for better performance. These enhanced designs can result in spindles that are more resistant to bending, warping, or premature wear, thereby increasing their durability.

- Specialized Spindles: In some cases, aftermarket axle spindles are designed for specific applications or driving conditions. For example, there may be spindles available that are specifically engineered for off-road use, providing improved ground clearance or compatibility with certain suspension systems. Likewise, there may be spindles designed for racing applications, where lightweight construction and enhanced performance characteristics are prioritized.

- Customization Options: Certain aftermarket manufacturers offer customized axle spindles that allow customers to tailor the spindles to their specific needs. This can include options for different bearing sizes, wheel bolt patterns, or spindle lengths to accommodate unique vehicle setups or modifications.

When considering aftermarket axle spindle options, it’s important to choose reputable manufacturers known for their quality and reliability. Look for spindles that meet industry standards and certifications, and consider factors such as the specific application, vehicle requirements, and intended use to ensure compatibility and optimal performance.

It’s also worth noting that while aftermarket axle spindles can offer enhanced durability or additional features, they may come at a higher cost compared to OEM replacements. However, the potential benefits in terms of improved performance, longevity, or customization options can make them a worthwhile investment, particularly for vehicles subjected to demanding conditions or specialized applications.

In summary, there are aftermarket axle spindle options available with enhanced durability or features. These may include performance spindles, upgraded materials, improved designs and engineering, specialized spindles, and customization options. When considering aftermarket spindles, it’s important to choose reputable manufacturers and consider factors such as compatibility, performance requirements, and intended use.

Can a damaged axle spindle lead to safety concerns, and how urgent is the need for repair?

Yes, a damaged axle spindle can indeed lead to safety concerns, and the need for repair is typically urgent. The axle spindle is a critical component of a vehicle’s suspension system and is responsible for supporting the weight of the vehicle and transmitting driving forces to the wheels. Here’s why a damaged axle spindle poses safety risks and requires prompt repair:

- 1. Steering Control: An axle spindle connects to the steering components and wheel hubs. Damage to the spindle can result in reduced steering control, making it challenging to maneuver the vehicle safely, especially in emergency situations.

- 2. Wheel Stability: The spindle supports the vehicle’s wheels. If the spindle is damaged, it can lead to wheel instability, wobbling, or even detachment. This poses a severe risk of accidents, especially at higher speeds.

- 3. Braking Performance: A damaged spindle can affect the alignment and performance of the braking system. This may result in uneven braking, longer stopping distances, or a loss of braking effectiveness, compromising safety during braking maneuvers.

- 4. Suspension Integrity: The axle spindle is a key structural component of the suspension system. A damaged spindle can weaken the overall suspension integrity, potentially leading to loss of control, swaying, or erratic handling.

- 5. Risk of Collisions: A vehicle with a damaged axle spindle may become unpredictable and pose a risk of colliding with other vehicles, obstacles, or pedestrians due to compromised stability and handling.

- 6. Towing and Hauling Risks: For vehicles used for towing or hauling heavy loads, a damaged spindle can lead to catastrophic failures when subjected to increased stress. This can result in accidents or loss of cargo.

- 7. Uneven Tire Wear: Axle spindle damage can cause uneven tire wear, reducing the tires’ grip and compromising traction, especially in adverse road conditions.

Given the critical role of the axle spindle in vehicle safety, any signs of damage or wear should be taken seriously, and repairs should be prioritized. Immediate inspection by a qualified mechanic is essential if you suspect spindle damage. Delaying repairs can lead to worsened safety risks, increased repair costs, and potential accidents. Regular vehicle maintenance and inspection can help detect spindle issues early and prevent safety concerns.

How does a damaged or bent axle spindle impact the performance of a vehicle?

A damaged or bent axle spindle can significantly impact the performance and safety of a vehicle. Here’s a detailed explanation:

When the axle spindle is damaged or bent, it can cause various issues that affect the overall performance and handling of the vehicle. Here are some ways a damaged or bent axle spindle can impact a vehicle:

- Wheel Misalignment: A damaged or bent axle spindle can result in wheel misalignment. This misalignment can cause uneven tire wear, reduced traction, and compromised handling. The vehicle may pull to one side, and the steering may feel unstable or imprecise. Wheel misalignment can also lead to increased rolling resistance, negatively impacting fuel efficiency.

- Vibration and Shaking: A bent axle spindle can cause vibrations and shaking in the vehicle, particularly at higher speeds. The imbalance created by the bent spindle can result in uneven tire rotation and wheel wobbling, leading to an uncomfortable and potentially unsafe driving experience.

- Braking Issues: A damaged axle spindle can affect the performance of the braking system. Uneven wheel rotation caused by a bent spindle can result in inconsistent braking force distribution. This can lead to longer braking distances, reduced braking efficiency, and potentially compromised safety in emergency braking situations.

- Suspension Component Stress: A damaged or bent axle spindle can place excessive stress on other suspension components, such as wheel bearings, control arms, or steering linkage. The misalignment and increased forces can accelerate wear and tear on these components, leading to premature failure and costly repairs.

- Handling and Stability: A compromised axle spindle can negatively impact the vehicle’s handling and stability. It can cause unpredictable steering response, reduced cornering ability, and decreased overall stability during maneuvers. This can increase the risk of loss of control and accidents, especially in emergency or evasive driving situations.

It’s important to address a damaged or bent axle spindle promptly. Continuing to drive with a damaged spindle can exacerbate the issues mentioned above and potentially cause further damage to other components of the suspension system. If you suspect a problem with the axle spindle, it’s recommended to have the vehicle inspected by a qualified mechanic or technician who can accurately diagnose the issue and perform the necessary repairs or replacement.

In summary, a damaged or bent axle spindle can have a significant impact on the performance and safety of a vehicle. It can cause wheel misalignment, vibrations, braking issues, stress on suspension components, and compromised handling and stability. Prompt attention and repair are crucial to ensure the vehicle’s optimal performance and to maintain safety on the road.

editor by CX 2024-04-25

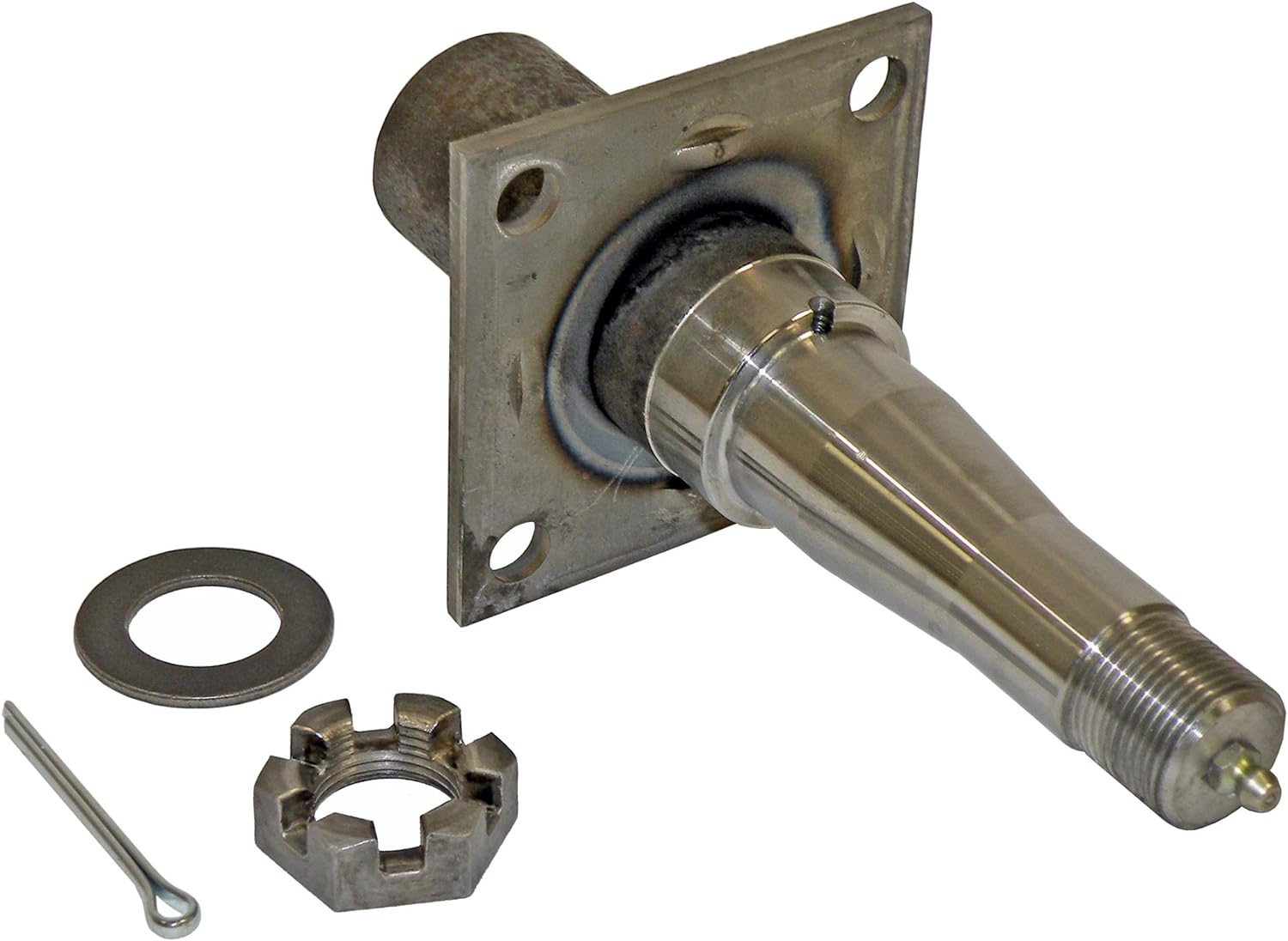

China Standard OEM Hot Forged Parts Trailer Axle Boat Trailer Part Drop Spindle Trailer Axle Spindle Shaft axle dump

Product Description

OEM hot forged parts Trailer Axle boat trailer part Drop Spindle Trailer Axle Spindle shaft

|

item |

value |

|

Place of Origin |

China |

|

Province |

ZheJiang |

|

Model Number |

Customized Services |

|

Process |

Mainly Hot forging, Some parts with Cold forging ,die forging and Free forgin will be OK |

|

Material |

Carbon steel: CM490,A36,1045,1035 etc., Alloy steel: 40Cr, 20CrMnTi, 20CrNiMo, 42CrMo4 etc., Stainless steel, SS304,SS316 etc. |

|

Weight |

1kg – 120kg |

|

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. |

|

Machining Tolerance |

0.03mm-0.1mm |

|

Applicable Finish Surface Treatment |

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, |

|

Testing equipment |

Supersonic inspection machine, Supersonic flaw detecting machine , physics and chemical analysis. |

|

MOQ of mass production |

1000-5000pcs |

|

Testing equipment |

Optical Spectrum Analyzer,tensile testing machine,impact testing machine,fluorescent magnetic particle detector,hardness tester,ultrasonic flaw detector..etc. |

|

Packing |

Wooden cases or according to customers’ needs |

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to North America(10.00%),South America(10.00%),Southeast

Asia(10.00%),Africa(10.00%),Mid East(10.00%),Eastern Asia(10.00%),Central America(10.00%),Northern Europe(10.00%),South

Asia(10.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

semi trailer axles, air suspensions , chamber,wheel ,slack adjuster and other related items.

4. why should you buy from us not from other suppliers?

We have a trailer parts production more than 10 years the supply chain

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

6.what is the certificate

At present, the company can undertake CCS, ABS, BV, GL and other certification products /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Available |

|---|---|

| Condition: | New |

| Application: | Trailer |

| Certification: | ASTM, CE, DIN, ISO |

| Material: | Steel |

| Transport Package: | Customized |

| Customization: |

Available

| Customized Request |

|---|

How do I properly inspect an axle spindle for signs of wear or damage?

Inspecting an axle spindle for signs of wear or damage is an important part of vehicle maintenance. Here is a detailed explanation of how to properly inspect an axle spindle:

Before starting the inspection, ensure the vehicle is safely supported on jack stands and the wheels are removed to provide clear access to the axle spindles. Here are the steps to follow:

- Visual Inspection: Begin by visually examining the axle spindle for any visible signs of wear, damage, or irregularities. Look for the following indications:

- Cracks or fractures on the spindle surface

- Bent or warped spindle

- Signs of excessive corrosion or rust

- Visible wear patterns or grooves

- Unusual discoloration or heat marks

- Tactile Inspection: Run your fingers along the surface of the spindle to feel for any roughness, pitting, or other abnormalities. Pay attention to any areas that feel excessively rough or have noticeable imperfections.

- Bearing Play: Check for excessive play or looseness in the wheel bearing by grasping the wheel at the top and bottom and attempting to move it back and forth. If there is noticeable play, it may indicate worn or damaged wheel bearings, which can affect the spindle’s performance.

- Runout Measurement: Using a dial indicator, measure the spindle’s runout. This involves checking for any deviation or wobbling of the spindle when it rotates. Attach the dial indicator to a fixed point on the suspension or brake assembly and position the indicator’s contact point against the spinning spindle. Slowly rotate the spindle and observe the dial indicator’s reading. Excessive runout can indicate a bent or warped spindle.

- Brake Component Alignment: Check the alignment of the brake components, including the brake rotor and caliper, in relation to the spindle. Ensure that the rotor sits flush against the spindle surface and that the caliper is properly aligned with the rotor. Misalignment can indicate a bent or damaged spindle.

- Seal and Bearing Inspection: If possible, remove the wheel bearing and seal to inspect them for any signs of damage, wear, or leakage. Look for pitting, excessive wear, or damaged seals. Replace the bearings and seals if necessary.

It’s important to note that axle spindle inspection may require specialized tools, such as a dial indicator or bearing puller. If you’re uncomfortable performing the inspection yourself or lack the necessary tools, it’s recommended to have a qualified mechanic or technician inspect the spindle for you.

Regular axle spindle inspections can help identify potential issues early on, allowing for timely repairs or replacements. If you notice any signs of wear, damage, or irregularities during the inspection, it’s advisable to consult a professional for further evaluation and necessary repairs.

In summary, properly inspecting an axle spindle involves a visual and tactile examination for signs of wear or damage, checking for bearing play, measuring runout, assessing brake component alignment, and inspecting the wheel bearings and seals. Follow the recommended steps and consider seeking professional assistance if needed.

Are there recalls or common issues associated with specific axle spindle models?

Recalls and common issues can occur with specific axle spindle models. Here is a detailed explanation:

Axle spindles are critical components of a vehicle’s suspension system, responsible for supporting the weight of the vehicle and allowing the wheels to rotate. While axle spindle issues are not as common as some other automotive problems, they can still arise in certain situations or with specific models. It’s important to note that recalls and common issues can vary depending on the vehicle make, model, and year. Therefore, it’s essential to consult the manufacturer’s documentation or contact authorized dealerships to obtain the most accurate and up-to-date information regarding recalls or known problems associated with specific axle spindle models.

Recalls are typically issued by vehicle manufacturers or regulatory agencies when a safety-related defect or non-compliance with safety standards is identified in a specific component or vehicle model. When it comes to axle spindles, recalls may be issued if there is evidence of a manufacturing defect, design flaw, or other issues that could compromise the performance, durability, or safety of the axle spindle. Recalls are intended to address these concerns and ensure that affected vehicles are repaired or modified to rectify the problem.

Common issues associated with specific axle spindle models can also arise due to various factors. These issues may be reported by vehicle owners, observed by mechanics or technicians, or identified through data analysis. Common issues can include premature wear, excessive play, bearing failures, or other forms of damage or deterioration that affect the functionality or reliability of the axle spindle.

To determine if there are any recalls or common issues associated with a specific axle spindle model, follow these steps:

- Refer to Manufacturer’s Documentation: Check the manufacturer’s documentation, such as owner’s manuals, maintenance guides, or technical service bulletins. These resources may provide information about known issues, recalls, or recommended maintenance procedures for the axle spindle.

- Contact Authorized Dealerships: Reach out to authorized dealerships or service centers for the vehicle make and model. They often have access to the latest information regarding recalls or common axle spindle issues. Provide them with the specific details of your vehicle, including the make, model, year, and vehicle identification number (VIN) if requested.

- Check Government Recall Databases: Government agencies responsible for vehicle safety, such as the National Highway Traffic Safety Administration (NHTSA) in the United States, maintain databases of recalls. Visit their websites and search for any recalls associated with the specific vehicle make, model, and year.

- Online Forums and Communities: Explore online automotive forums and communities dedicated to the specific vehicle make or model. These platforms often provide valuable insights from owners who may have encountered axle spindle issues or recalls. However, exercise caution and verify the information obtained from such sources, as it may not always be accurate or up to date.

By following these steps, you can gather information about recalls or common issues associated with specific axle spindle models. If a recall or known issue is identified, it’s important to take appropriate action by contacting authorized repair facilities or dealerships to address the problem promptly.

It’s worth noting that not all axle spindle models may have recalls or common issues. Vehicle manufacturers strive to design and produce reliable components, and any potential problems are typically addressed through quality control measures and continuous improvement processes. However, occasional issues can still arise, particularly in specific production runs or under certain operating conditions.

In summary, recalls and common issues can occur with specific axle spindle models. Recalls are typically issued by manufacturers or regulatory agencies to address safety-related defects or non-compliance with safety standards. Common issues can include premature wear, excessive play, bearing failures, or other forms of damage or deterioration. To obtain accurate information about recalls or known issues, refer to the manufacturer’s documentation, contact authorized dealerships, check government recall databases, and explore online forums and communities dedicated to the specific vehicle make or model.

How does a damaged or bent axle spindle impact the performance of a vehicle?

A damaged or bent axle spindle can significantly impact the performance and safety of a vehicle. Here’s a detailed explanation:

When the axle spindle is damaged or bent, it can cause various issues that affect the overall performance and handling of the vehicle. Here are some ways a damaged or bent axle spindle can impact a vehicle:

- Wheel Misalignment: A damaged or bent axle spindle can result in wheel misalignment. This misalignment can cause uneven tire wear, reduced traction, and compromised handling. The vehicle may pull to one side, and the steering may feel unstable or imprecise. Wheel misalignment can also lead to increased rolling resistance, negatively impacting fuel efficiency.

- Vibration and Shaking: A bent axle spindle can cause vibrations and shaking in the vehicle, particularly at higher speeds. The imbalance created by the bent spindle can result in uneven tire rotation and wheel wobbling, leading to an uncomfortable and potentially unsafe driving experience.

- Braking Issues: A damaged axle spindle can affect the performance of the braking system. Uneven wheel rotation caused by a bent spindle can result in inconsistent braking force distribution. This can lead to longer braking distances, reduced braking efficiency, and potentially compromised safety in emergency braking situations.

- Suspension Component Stress: A damaged or bent axle spindle can place excessive stress on other suspension components, such as wheel bearings, control arms, or steering linkage. The misalignment and increased forces can accelerate wear and tear on these components, leading to premature failure and costly repairs.

- Handling and Stability: A compromised axle spindle can negatively impact the vehicle’s handling and stability. It can cause unpredictable steering response, reduced cornering ability, and decreased overall stability during maneuvers. This can increase the risk of loss of control and accidents, especially in emergency or evasive driving situations.

It’s important to address a damaged or bent axle spindle promptly. Continuing to drive with a damaged spindle can exacerbate the issues mentioned above and potentially cause further damage to other components of the suspension system. If you suspect a problem with the axle spindle, it’s recommended to have the vehicle inspected by a qualified mechanic or technician who can accurately diagnose the issue and perform the necessary repairs or replacement.

In summary, a damaged or bent axle spindle can have a significant impact on the performance and safety of a vehicle. It can cause wheel misalignment, vibrations, braking issues, stress on suspension components, and compromised handling and stability. Prompt attention and repair are crucial to ensure the vehicle’s optimal performance and to maintain safety on the road.

editor by CX 2024-04-12

China Professional 3500lbs Capacity Trailer Steel Forging Drop Shaft Spindles for Agriculture Axle Parts axle definition

Product Description

1750lbs 3500lbs Capacity Trailer Steel Forging Drop Spindles for Axle Parts

Wide range of sizes with quality stub axles available. Axles are very easy to replace. Sturdy steel construction to ensure durability.

| Part Number | Description | Capacity | Brake Flange | Bearings ID | Bearings no. | Stub Length | Grease Seal ID |

| S1008 | Round Spindle Dia.1.25″,BT8 | 1000 lbs | W/O | 1″x1″ | L44643 x2 | Customized | 1.24″ |

| S1016 | Round Spindle Dia.1.25″,BT16 | 1000 lbs | W/O | 1.06″x1.06″ | L44649 x2 | Customized | 1.24″ |

| S125016 | Round Spindle Dia.1.57″,BT16 | 1250 lbs | W/O | 1.06″x1.06″ | L44649 x2 | Customized | 1.5″ |

| S175084 | Round Spindle Dia.1.75″,#84 | 1750 lbs | W/O | 1.38″x1.06″ | L68149 x L44649 | Customized | 1.73″ |

| S3042 | Round Spindle Dia.2.25″,#42 | 3000 lbs | W/O | 1.74″x1.25″ | 25580 x 15123 | Customized | 2.24″ |

| S175084F | Round Spindle Dia.1.75″,#84 | 1750 lbs | Yes | 1.38″x1.06″ | L68149 x L44649 | Customized | 1.73″ |

| S3042F | Round Spindle Dia.2.25″,#42 | 3000 lbs | Yes | 1.74″x1.25″ | 25580 x 15123 | Customized | 2.24″ |

| S750R39 | 39mm Round Stub Axle | 750 kg/pr | W/O | LM Bearings | LM67048 x LM11949 | Customized | 36.5mm |

| S10S40 | 40mm Square Stub Axle | 1000 kg/pr | W/O | LM Bearings | LM67048 x LM11949 | Customized | 36.5mm |

| S1250S45 | 45mm Square Stub Axle | 1250 kg/pr | W/O | SL Bearings | L68149 x LM12749 | Customized | 42mm |

| S1250R50 | 50mm Round Stub Axle | 1250 kg/pr | W/O | SL Bearings | L68149 x LM12749 | Customized | 42mm |

| S15S45 | 45mm Square Stub Axle | 1500 kg/pr | W/O | 1.5T Bearings | LM29749 x L44649 | Customized | 44.45mm |

| S15R50 | 50mm Round Stub Axle | 1500 kg/pr | W/O | 1.5T Bearings | LM29749 x L44649 | Customized | 44.45mm |

| S15S45P | 45mm Square Stub Axle Parallel | 1500 kg/pr | W/O | Parallel | L68149 x L68149 | Customized | 42mm |

| S20S50 | 50mm Square Stub Axle | 2000 kg/pr | W/O | 2.0T Bearings | 25580 x LM67048 | Customized | 55mm |

| S20R56 | 56mm Round Stub Axle | 2000 kg/pr | W/O | 2.0T Bearings | 25580 x LM67048 | Customized | 55mm |

| S30R63 | 63mm Round Stub Axle | 3000 kg/pr | W/O | 3.0T Bearings | 35710 x LM29749 | Customized | 61mm |

1) Do you have factory?

CZPT :

Yes, we have our own factory, own engineers, we can meet custom’s unique requirement.

2) Do you provide sample? Free or charge?

CZPT :

Sample can be submitted for clients check and approval ; Normal sample will be take cost and can be consider to return back since order be placed.

3) What is your MOQ?

CZPT :

MOQ 1-200 for trailer axles & hubs.

MOQ 3000 for trailer parts assembly

4) Can you manufacture the parts according to our size?

CZPT :

Depend on make tooling we can support your to be achieved your fixed request size for items.

5) What is your term of payment?

CZPT :

Normally for bulk TT., Irrevocable L/C at sight will be workable.

For samples , Paypal can be accept.

6) How long is your delivery time?

CZPT :

Normal 25 working days for delivery ;

CZPT time be about 35 working days.

7) Can I delivery the goods from other supplier to your factory? Then load together?

CZPT :

Sure ,we can accept and support. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small (28-55mm) |

| Material: | Steel, Alloy |

| Spherical: | Aligning Bearings |

| Load Direction: | Axial Bearing |

| Customization: |

Available

| Customized Request |

|---|

Can a malfunctioning axle spindle lead to brake-related issues, and if so, how?

Yes, a malfunctioning axle spindle can indeed lead to brake-related issues in a vehicle. Here is a detailed explanation of how a faulty axle spindle can affect the brake system:

The axle spindle plays a crucial role in the operation of the brake system, particularly in vehicles with disc brakes. It is responsible for supporting the wheel hub and providing a mounting point for various brake components, such as the brake rotor, caliper, and brake pads. When the axle spindle malfunctions, it can have several adverse effects on the brake system, including the following:

- Uneven Brake Pad Wear: A malfunctioning axle spindle can cause uneven distribution of braking force on the brake rotor. This uneven force can lead to uneven wear of the brake pads. Some pads may wear out faster than others, resulting in uneven braking performance and reduced effectiveness.

- Brake Caliper Misalignment: If the axle spindle becomes bent or damaged, it can cause misalignment of the brake caliper. The caliper may not sit properly over the brake rotor, resulting in uneven braking force or even constant contact between the brake pads and rotor. This can lead to excessive heat, premature wear of brake components, and reduced braking efficiency.

- Brake Vibration and Noise: A malfunctioning axle spindle can cause vibrations and noise during braking. For example, if the spindle is bent or warped, it can create an uneven surface for the brake rotor. As a result, when the brake pads come into contact with the rotor, it can cause vibrations, squealing, or grinding noises. These symptoms indicate a compromised braking performance and the need for axle spindle inspection and repair.

- Wheel Bearing Damage: The axle spindle is closely connected to the wheel bearing assembly. If the spindle is damaged or improperly aligned, it can put excessive stress on the wheel bearing, leading to its premature wear or failure. A worn or damaged wheel bearing can introduce additional friction, affect wheel rotation, and potentially cause overheating of the brake components.

- Brake Fluid Leakage: In certain cases, a malfunctioning axle spindle can result in damage to the brake lines or connections. For example, if the spindle is severely damaged due to an accident or collision, it can cause brake fluid leakage. Brake fluid leakage compromises the hydraulic pressure in the brake system, leading to reduced braking performance or a complete brake failure.

It’s important to note that the specific brake-related issues resulting from a malfunctioning axle spindle can vary depending on the extent and nature of the spindle’s malfunction. Regular inspection and maintenance of the axle spindle, along with the brake system, are essential to identify any potential issues early and prevent further damage.

If you experience any brake-related symptoms or suspect a malfunctioning axle spindle, it is crucial to have the vehicle inspected by a qualified mechanic or technician. They can assess the condition of the axle spindle, perform necessary repairs or replacements, and ensure the proper functioning of the brake system for safe driving.

In summary, a malfunctioning axle spindle can lead to various brake-related issues, including uneven brake pad wear, brake caliper misalignment, brake vibration and noise, wheel bearing damage, and brake fluid leakage. Regular inspection and maintenance of the axle spindle and brake system are essential to prevent these issues and maintain optimal braking performance.

Where can I find reputable suppliers for purchasing replacement axle spindle parts?

Finding reputable suppliers for purchasing replacement axle spindle parts is crucial to ensure the quality, compatibility, and reliability of the parts you acquire. Here are several reliable sources where you can find reputable suppliers:

- Authorized Dealerships: Contacting authorized dealerships of the vehicle manufacturer is often a reliable option. They have direct access to genuine replacement parts, including axle spindles, that are specifically designed for your vehicle make and model. Authorized dealerships can ensure the authenticity and quality of the parts they provide.

- Specialized Automotive Parts Retailers: There are reputable retailers specializing in automotive parts and accessories. These retailers may have a wide selection of replacement axle spindle parts from various manufacturers. Look for well-established retailers with a good reputation, positive customer reviews, and a track record of providing high-quality products.

- Online Marketplaces: Online marketplaces can offer a convenient way to find and purchase replacement axle spindle parts. Platforms such as Amazon, eBay, or specialized automotive marketplaces provide access to a broad range of suppliers and sellers. When using online marketplaces, pay attention to seller ratings, customer reviews, and product descriptions to ensure you are dealing with reputable sellers and purchasing genuine parts.

- Manufacturer Websites: Visit the official websites of axle spindle manufacturers. Many manufacturers have online catalogs or directories that allow you to search for authorized distributors or dealers in your region. Purchasing directly from the manufacturer or their authorized distributors can ensure the authenticity and quality of the parts.

- Local Auto Parts Stores: Local auto parts stores can be a convenient option for purchasing replacement axle spindle parts. Well-established stores with knowledgeable staff can assist you in finding the right parts, provide guidance on compatibility, and ensure you are purchasing from reputable suppliers. Some local stores may have access to a network of suppliers, making it easier to find specific parts.

- Recommendations and Referrals: Reach out to trusted mechanics, automotive enthusiasts, or fellow vehicle owners for recommendations on reputable suppliers. They may have firsthand experience with certain suppliers or brands and can provide valuable insights on where to find reliable replacement axle spindle parts.

When sourcing axle spindle parts, it is important to consider factors such as the reputation of the supplier, the authenticity of the parts, warranty policies, return or exchange options, and customer support. Additionally, verify the compatibility of the parts with your specific vehicle make, model, and year to ensure a proper fit and optimal performance.

By utilizing these reliable sources and conducting due diligence in selecting reputable suppliers, you can increase the likelihood of finding high-quality replacement axle spindle parts for your vehicle.

Can a DIY enthusiast replace a damaged axle spindle, and what are the steps involved?

Replacing a damaged axle spindle is a complex mechanical task that requires advanced knowledge and specialized tools. It is generally recommended to seek the assistance of a professional mechanic or technician for such a repair. However, if you have the necessary expertise, experience, and access to the appropriate tools, it may be possible for a skilled DIY enthusiast to replace a damaged axle spindle. Here are the general steps involved in replacing an axle spindle:

Note: The following steps provide a general outline of the process, but it’s important to consult the specific repair manual for your vehicle and follow the manufacturer’s instructions.

- Preparation: Begin by ensuring that you have the correct replacement axle spindle that matches the specifications of your vehicle. Gather all the necessary tools and equipment required for the job, including a hydraulic jack, jack stands, socket set, wrenches, pry bar, torque wrench, and any specialized tools mentioned in the repair manual.

- Vehicle Preparation: Park the vehicle on a level surface and engage the parking brake. If the axle spindle to be replaced is on the front axle, turn the steering wheel to the straight-ahead position. If it’s on the rear axle, chock the front wheels to prevent the vehicle from rolling.

- Suspension Disassembly: Depending on the vehicle’s design, you may need to remove certain components to access the axle spindle. This can include removing the wheel, brake caliper, brake rotor or drum, tie rod ends, ball joints, axle shafts, and any other components obstructing the spindle’s removal. Follow the repair manual instructions for proper disassembly.

- Axle Spindle Removal: Once the suspension components are removed, you can proceed with removing the damaged axle spindle. This typically involves disconnecting any remaining attachments, such as mounting bolts or fasteners, and carefully maneuvering the spindle out of its housing. Take care not to damage surrounding components or disturb other parts of the suspension system.

- Axle Spindle Installation: Install the replacement axle spindle by following the reverse order of the removal steps. Carefully position the spindle back into its housing, ensuring proper alignment. Reattach any fasteners or mounting bolts according to the specified torque values. Take care to follow the manufacturer’s instructions for any specific procedures or considerations during installation.

- Suspension Reassembly: Reinstall all the components that were removed during the disassembly process, including brake calipers, rotors or drums, tie rod ends, ball joints, axle shafts, and any other relevant parts. Ensure that all connections are secure and torqued to the specified values.

- Final Checks: Double-check all the connections, fasteners, and components to ensure everything is properly reassembled. Confirm that the axle spindle is securely in place and aligned correctly. Before lowering the vehicle, perform a thorough inspection of the suspension system to ensure there are no loose or forgotten components.

- Testing and Alignment: Once the replacement axle spindle is installed, it’s important to have the vehicle’s alignment checked and adjusted by a professional. Improper alignment can lead to uneven tire wear, handling issues, and compromised safety. Schedule a visit to an alignment specialist to ensure the vehicle’s alignment is within the recommended specifications.

It’s crucial to note that replacing an axle spindle involves working with critical components of the vehicle’s suspension and steering systems. Misinstallation or improper assembly can lead to severe safety risks and further damage to the vehicle. If you are unsure or lack the experience and expertise, it is strongly recommended to entrust the task to a qualified professional mechanic or technician.

In summary, while a skilled DIY enthusiast may be able to replace a damaged axle spindle, it is a complex task that requires advanced knowledge, experience, and specialized tools. It’s important to follow the manufacturer’s instructions, consult the repair manual for your specific vehicle, and exercise caution throughout the process. If in doubt, it’s best to seek professional assistance to ensure the job is done safely and correctly.

editor by CX 2024-02-08

China Professional OEM Hot Forged Parts Trailer Axle Boat Trailer Part Drop Spindle Trailer Axle Spindle Shaft axle end caps

Product Description

OEM hot forged parts Trailer Axle boat trailer part Drop Spindle Trailer Axle Spindle shaft

|

item |

value |

|

Place of Origin |

China |

|

Province |

ZheJiang |

|

Model Number |

Customized Services |

|

Process |

Mainly Hot forging, Some parts with Cold forging ,die forging and Free forgin will be OK |

|

Material |

Carbon steel: CM490,A36,1045,1035 etc., Alloy steel: 40Cr, 20CrMnTi, 20CrNiMo, 42CrMo4 etc., Stainless steel, SS304,SS316 etc. |

|

Weight |

1kg – 120kg |

|

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. |

|

Machining Tolerance |

0.03mm-0.1mm |

|

Applicable Finish Surface Treatment |

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, |

|

Testing equipment |

Supersonic inspection machine, Supersonic flaw detecting machine , physics and chemical analysis. |

|

MOQ of mass production |

1000-5000pcs |

|

Testing equipment |

Optical Spectrum Analyzer,tensile testing machine,impact testing machine,fluorescent magnetic particle detector,hardness tester,ultrasonic flaw detector..etc. |

|

Packing |

Wooden cases or according to customers’ needs |

1. who are we?

We are based in ZheJiang , China, start from 2571,sell to North America(10.00%),South America(10.00%),Southeast

Asia(10.00%),Africa(10.00%),Mid East(10.00%),Eastern Asia(10.00%),Central America(10.00%),Northern Europe(10.00%),South

Asia(10.00%),Domestic Market(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

semi trailer axles, air suspensions , chamber,wheel ,slack adjuster and other related items.

4. why should you buy from us not from other suppliers?

We have a trailer parts production more than 10 years the supply chain

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese

6.what is the certificate

At present, the company can undertake CCS, ABS, BV, GL and other certification products

| After-sales Service: | Available |

|---|---|

| Condition: | New |

| Application: | Trailer |

| Certification: | ASTM, CE, DIN, ISO |

| Material: | Steel |

| Transport Package: | Customized |

| Customization: |

Available

| Customized Request |

|---|

Are there aftermarket axle spindle options available with enhanced durability or features?

Yes, there are aftermarket axle spindle options available that offer enhanced durability or additional features compared to the original equipment manufacturer (OEM) spindles. Here is a detailed explanation:

Aftermarket parts are manufactured by companies other than the vehicle’s original manufacturer. These companies often specialize in producing high-quality replacement parts that may offer improvements over the OEM components. When it comes to axle spindles, some aftermarket options are designed to provide enhanced durability or incorporate features that can benefit specific applications or driving conditions.

Here are a few examples of aftermarket axle spindle options with enhanced durability or features:

- Performance Spindles: Some aftermarket manufacturers offer performance-oriented axle spindles that are designed to handle higher loads and stress levels. These spindles are commonly used in applications where increased durability and strength are required, such as heavy-duty trucks, off-road vehicles, or vehicles used for towing. Performance spindles may be made of stronger materials or feature reinforced designs to withstand more demanding conditions.

- Upgraded Materials: Aftermarket axle spindles may be manufactured using advanced materials that offer improved strength and corrosion resistance compared to the original spindles. For example, spindles made from alloy steel or heat-treated steel alloys can provide enhanced durability and longevity, especially in harsh environments or applications subject to heavy loads.

- Improved Design and Engineering: Aftermarket manufacturers often analyze the weaknesses or limitations of OEM spindles and develop improved designs to address those issues. This may involve optimizing the geometry, reinforcing critical areas, or incorporating additional features for better performance. These enhanced designs can result in spindles that are more resistant to bending, warping, or premature wear, thereby increasing their durability.

- Specialized Spindles: In some cases, aftermarket axle spindles are designed for specific applications or driving conditions. For example, there may be spindles available that are specifically engineered for off-road use, providing improved ground clearance or compatibility with certain suspension systems. Likewise, there may be spindles designed for racing applications, where lightweight construction and enhanced performance characteristics are prioritized.

- Customization Options: Certain aftermarket manufacturers offer customized axle spindles that allow customers to tailor the spindles to their specific needs. This can include options for different bearing sizes, wheel bolt patterns, or spindle lengths to accommodate unique vehicle setups or modifications.

When considering aftermarket axle spindle options, it’s important to choose reputable manufacturers known for their quality and reliability. Look for spindles that meet industry standards and certifications, and consider factors such as the specific application, vehicle requirements, and intended use to ensure compatibility and optimal performance.

It’s also worth noting that while aftermarket axle spindles can offer enhanced durability or additional features, they may come at a higher cost compared to OEM replacements. However, the potential benefits in terms of improved performance, longevity, or customization options can make them a worthwhile investment, particularly for vehicles subjected to demanding conditions or specialized applications.

In summary, there are aftermarket axle spindle options available with enhanced durability or features. These may include performance spindles, upgraded materials, improved designs and engineering, specialized spindles, and customization options. When considering aftermarket spindles, it’s important to choose reputable manufacturers and consider factors such as compatibility, performance requirements, and intended use.

Where can I find reputable suppliers for purchasing replacement axle spindle parts?

Finding reputable suppliers for purchasing replacement axle spindle parts is crucial to ensure the quality, compatibility, and reliability of the parts you acquire. Here are several reliable sources where you can find reputable suppliers:

- Authorized Dealerships: Contacting authorized dealerships of the vehicle manufacturer is often a reliable option. They have direct access to genuine replacement parts, including axle spindles, that are specifically designed for your vehicle make and model. Authorized dealerships can ensure the authenticity and quality of the parts they provide.

- Specialized Automotive Parts Retailers: There are reputable retailers specializing in automotive parts and accessories. These retailers may have a wide selection of replacement axle spindle parts from various manufacturers. Look for well-established retailers with a good reputation, positive customer reviews, and a track record of providing high-quality products.

- Online Marketplaces: Online marketplaces can offer a convenient way to find and purchase replacement axle spindle parts. Platforms such as Amazon, eBay, or specialized automotive marketplaces provide access to a broad range of suppliers and sellers. When using online marketplaces, pay attention to seller ratings, customer reviews, and product descriptions to ensure you are dealing with reputable sellers and purchasing genuine parts.

- Manufacturer Websites: Visit the official websites of axle spindle manufacturers. Many manufacturers have online catalogs or directories that allow you to search for authorized distributors or dealers in your region. Purchasing directly from the manufacturer or their authorized distributors can ensure the authenticity and quality of the parts.

- Local Auto Parts Stores: Local auto parts stores can be a convenient option for purchasing replacement axle spindle parts. Well-established stores with knowledgeable staff can assist you in finding the right parts, provide guidance on compatibility, and ensure you are purchasing from reputable suppliers. Some local stores may have access to a network of suppliers, making it easier to find specific parts.

- Recommendations and Referrals: Reach out to trusted mechanics, automotive enthusiasts, or fellow vehicle owners for recommendations on reputable suppliers. They may have firsthand experience with certain suppliers or brands and can provide valuable insights on where to find reliable replacement axle spindle parts.

When sourcing axle spindle parts, it is important to consider factors such as the reputation of the supplier, the authenticity of the parts, warranty policies, return or exchange options, and customer support. Additionally, verify the compatibility of the parts with your specific vehicle make, model, and year to ensure a proper fit and optimal performance.

By utilizing these reliable sources and conducting due diligence in selecting reputable suppliers, you can increase the likelihood of finding high-quality replacement axle spindle parts for your vehicle.

How does a damaged or bent axle spindle impact the performance of a vehicle?

A damaged or bent axle spindle can significantly impact the performance and safety of a vehicle. Here’s a detailed explanation:

When the axle spindle is damaged or bent, it can cause various issues that affect the overall performance and handling of the vehicle. Here are some ways a damaged or bent axle spindle can impact a vehicle:

- Wheel Misalignment: A damaged or bent axle spindle can result in wheel misalignment. This misalignment can cause uneven tire wear, reduced traction, and compromised handling. The vehicle may pull to one side, and the steering may feel unstable or imprecise. Wheel misalignment can also lead to increased rolling resistance, negatively impacting fuel efficiency.

- Vibration and Shaking: A bent axle spindle can cause vibrations and shaking in the vehicle, particularly at higher speeds. The imbalance created by the bent spindle can result in uneven tire rotation and wheel wobbling, leading to an uncomfortable and potentially unsafe driving experience.

- Braking Issues: A damaged axle spindle can affect the performance of the braking system. Uneven wheel rotation caused by a bent spindle can result in inconsistent braking force distribution. This can lead to longer braking distances, reduced braking efficiency, and potentially compromised safety in emergency braking situations.

- Suspension Component Stress: A damaged or bent axle spindle can place excessive stress on other suspension components, such as wheel bearings, control arms, or steering linkage. The misalignment and increased forces can accelerate wear and tear on these components, leading to premature failure and costly repairs.

- Handling and Stability: A compromised axle spindle can negatively impact the vehicle’s handling and stability. It can cause unpredictable steering response, reduced cornering ability, and decreased overall stability during maneuvers. This can increase the risk of loss of control and accidents, especially in emergency or evasive driving situations.

It’s important to address a damaged or bent axle spindle promptly. Continuing to drive with a damaged spindle can exacerbate the issues mentioned above and potentially cause further damage to other components of the suspension system. If you suspect a problem with the axle spindle, it’s recommended to have the vehicle inspected by a qualified mechanic or technician who can accurately diagnose the issue and perform the necessary repairs or replacement.

In summary, a damaged or bent axle spindle can have a significant impact on the performance and safety of a vehicle. It can cause wheel misalignment, vibrations, braking issues, stress on suspension components, and compromised handling and stability. Prompt attention and repair are crucial to ensure the vehicle’s optimal performance and to maintain safety on the road.

editor by CX 2023-12-08

China factory Manufacturer Fabricated CNC Machining Customized Parts Mechanical Shaft Slender Shaft Step Eccentric Axle Wobble Spindle as thru axle

Product Description

Product Description

Warranty

1 Year

Applicable Industries

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Weight (KG)

1

Showroom Location

Viet Nam

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

Ordinary Product

Warranty of core components

1 Year

Core Components

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Material

steel

Place of Origin

ZheJiang , China

Condition

New

Structure

Shaft

Coatings

Customized

Torque Capacity

Customized

Model Number

Customized

Brand Name

NON

Description

Shaft

Machining equipment

CNC mill,lathe and grind machine

Material

stainless steel, aluminium, carbon

Surface

Grinding and polishing

Shape

Customized

Sampling time

10days

Production time

20days

Packing

Protective packing

Tolerance

±0.001

OEM

Welcome

Production Process

Company Profile

HangZhou HUANENGDA SPRING CO.,LTD

HangZhou HuaNengDa Spring Co., Ltd. is located in Tong ‘an District, HangZhou City, ZheJiang Province, China. It is a hardware factory specializing in R&D design, manufacture and sales of precision components. The company introduces domestic and foreign advanced equipment and production technology, adopts CNC high-precision computer machine, compression spring machine, CNC five-axis linkage machining center, CNC turning and milling compound, 300 tons of punch and other mechanical equipment,and employs senior engineers with more than 10 years of work experience to debug mechanical equipment and customize production.

With the business philosophy of honesty, pragmatism and excellence, HuaNengDa Spring Company is dedicated to serving customers at home and abroad. We hope that the products of HuaNengDa will help your business to be more brilliant, let us build a bright future in the high-tech era!

The testimony is pragmatic and the attitude of the people. Quality service is the pursuit of the people!

Factory Workshop

Production Procedur

Quality Inspection

Packing And Shipping

Our Service

FAQ

1.Small order quantity is workable

From the initial sample design of the spring to the mass production of the springs, we can quickly reach your manufacturing goals and immediately provide the best products because we have an excellent production management system and expertly trained technical personnel.

2.Committed to high quality production

To keep HuaNengDa Springs at the forefront of the industry, we have implemented a stringent internal quality control system and regularly import the latest manufacturing equipment and instruments. Through our precise manufacturing technology and expert mold making process, we provide our customers with the best products and service.

3.Efficiency in manufacturing

Our company’s machinery and equipment are controlled by CNC computers. In order to respond to international needs and standards, we continuously update and upgrade our equipment every year. Our machines effectively increase production capacity and save on manufacturing costs. The manufacturing department is the most important core of the whole company and by treating it with utmost importance, we reap great benefits in manufacturing efficiency.

4.Excellent customization services

HuaNengDa’s R&D team designs and completes customized products according to the needs of customers. From the selection of materials to the function of the products, we can design and develop products to suite different customers’ requirements. We are constantly involving ourselves in all aspects of the industry because only by having a complete view and analysis of the industry, can there be innovative breakthroughs.

Payment term

*T/T : 30% pre T/T, 70% before delivery.

*Trade Assurance

Service

*Delivery on time.

*Shipped by a convenient and cost-effective way.

*Good after-selling, 24 hours service for you.

Packing

*A: Poly bag, Plstic tray ,small box, carton.

*B: According to customers’ requirements.

Delivery

*Sample: 7-10 days after deposit received.

*Batch goods: 12-15 days after samples approved.

| Condition: | New |

|---|---|

| Certification: | ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Steel,Stainless Steel,Iron |

| Application: | Metal Processing Machinery Parts |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do I properly inspect an axle spindle for signs of wear or damage?

Inspecting an axle spindle for signs of wear or damage is an important part of vehicle maintenance. Here is a detailed explanation of how to properly inspect an axle spindle:

Before starting the inspection, ensure the vehicle is safely supported on jack stands and the wheels are removed to provide clear access to the axle spindles. Here are the steps to follow:

- Visual Inspection: Begin by visually examining the axle spindle for any visible signs of wear, damage, or irregularities. Look for the following indications:

- Cracks or fractures on the spindle surface

- Bent or warped spindle

- Signs of excessive corrosion or rust

- Visible wear patterns or grooves

- Unusual discoloration or heat marks

- Tactile Inspection: Run your fingers along the surface of the spindle to feel for any roughness, pitting, or other abnormalities. Pay attention to any areas that feel excessively rough or have noticeable imperfections.

- Bearing Play: Check for excessive play or looseness in the wheel bearing by grasping the wheel at the top and bottom and attempting to move it back and forth. If there is noticeable play, it may indicate worn or damaged wheel bearings, which can affect the spindle’s performance.

- Runout Measurement: Using a dial indicator, measure the spindle’s runout. This involves checking for any deviation or wobbling of the spindle when it rotates. Attach the dial indicator to a fixed point on the suspension or brake assembly and position the indicator’s contact point against the spinning spindle. Slowly rotate the spindle and observe the dial indicator’s reading. Excessive runout can indicate a bent or warped spindle.

- Brake Component Alignment: Check the alignment of the brake components, including the brake rotor and caliper, in relation to the spindle. Ensure that the rotor sits flush against the spindle surface and that the caliper is properly aligned with the rotor. Misalignment can indicate a bent or damaged spindle.

- Seal and Bearing Inspection: If possible, remove the wheel bearing and seal to inspect them for any signs of damage, wear, or leakage. Look for pitting, excessive wear, or damaged seals. Replace the bearings and seals if necessary.

It’s important to note that axle spindle inspection may require specialized tools, such as a dial indicator or bearing puller. If you’re uncomfortable performing the inspection yourself or lack the necessary tools, it’s recommended to have a qualified mechanic or technician inspect the spindle for you.

Regular axle spindle inspections can help identify potential issues early on, allowing for timely repairs or replacements. If you notice any signs of wear, damage, or irregularities during the inspection, it’s advisable to consult a professional for further evaluation and necessary repairs.

In summary, properly inspecting an axle spindle involves a visual and tactile examination for signs of wear or damage, checking for bearing play, measuring runout, assessing brake component alignment, and inspecting the wheel bearings and seals. Follow the recommended steps and consider seeking professional assistance if needed.

Where can I find reputable suppliers for purchasing replacement axle spindle parts?

Finding reputable suppliers for purchasing replacement axle spindle parts is crucial to ensure the quality, compatibility, and reliability of the parts you acquire. Here are several reliable sources where you can find reputable suppliers:

- Authorized Dealerships: Contacting authorized dealerships of the vehicle manufacturer is often a reliable option. They have direct access to genuine replacement parts, including axle spindles, that are specifically designed for your vehicle make and model. Authorized dealerships can ensure the authenticity and quality of the parts they provide.

- Specialized Automotive Parts Retailers: There are reputable retailers specializing in automotive parts and accessories. These retailers may have a wide selection of replacement axle spindle parts from various manufacturers. Look for well-established retailers with a good reputation, positive customer reviews, and a track record of providing high-quality products.

- Online Marketplaces: Online marketplaces can offer a convenient way to find and purchase replacement axle spindle parts. Platforms such as Amazon, eBay, or specialized automotive marketplaces provide access to a broad range of suppliers and sellers. When using online marketplaces, pay attention to seller ratings, customer reviews, and product descriptions to ensure you are dealing with reputable sellers and purchasing genuine parts.

- Manufacturer Websites: Visit the official websites of axle spindle manufacturers. Many manufacturers have online catalogs or directories that allow you to search for authorized distributors or dealers in your region. Purchasing directly from the manufacturer or their authorized distributors can ensure the authenticity and quality of the parts.

- Local Auto Parts Stores: Local auto parts stores can be a convenient option for purchasing replacement axle spindle parts. Well-established stores with knowledgeable staff can assist you in finding the right parts, provide guidance on compatibility, and ensure you are purchasing from reputable suppliers. Some local stores may have access to a network of suppliers, making it easier to find specific parts.

- Recommendations and Referrals: Reach out to trusted mechanics, automotive enthusiasts, or fellow vehicle owners for recommendations on reputable suppliers. They may have firsthand experience with certain suppliers or brands and can provide valuable insights on where to find reliable replacement axle spindle parts.

When sourcing axle spindle parts, it is important to consider factors such as the reputation of the supplier, the authenticity of the parts, warranty policies, return or exchange options, and customer support. Additionally, verify the compatibility of the parts with your specific vehicle make, model, and year to ensure a proper fit and optimal performance.

By utilizing these reliable sources and conducting due diligence in selecting reputable suppliers, you can increase the likelihood of finding high-quality replacement axle spindle parts for your vehicle.

What are the common signs of a worn or faulty axle spindle, and how can they be identified?

A worn or faulty axle spindle can exhibit several common signs that indicate potential issues. Here’s a detailed explanation:

Identifying a worn or faulty axle spindle requires careful observation of the vehicle’s behavior and performance. Here are some common signs that may indicate problems with the axle spindle:

- Uneven Tire Wear: Excessive or uneven tire wear is often a sign of a worn or faulty axle spindle. Inspect the tires regularly and look for patterns of wear, such as excessive wear on the edges, scalloping, cupping, or feathering. Uneven tire wear suggests that the spindle is not properly supporting the wheel assembly or that the alignment is compromised.

- Steering Instability: A worn or faulty axle spindle can cause steering instability. If you notice that the steering feels loose, imprecise, or requires constant correction while driving, it could be a sign of a problem with the spindle. Pay attention to any vibrations or shimmying sensations felt through the steering wheel, as these can also indicate issues with the axle spindle.

- Pulling or Drifting: If the vehicle consistently pulls to one side or drifts off-center, it may be due to a worn or faulty axle spindle. This misalignment can cause uneven tire wear and affect the vehicle’s stability and handling. Keep an eye on the vehicle’s tendency to deviate from a straight path while driving on a level road.

- Noise or Grinding: A worn or faulty axle spindle can produce unusual noises. Listen for any grinding, clicking, or humming sounds coming from the wheel area while driving, especially during turns. These noises may indicate worn or damaged bearings within the spindle assembly, which require immediate attention.

- Excessive Play or Movement: Check for excessive play or movement in the wheel assembly by firmly gripping the tire at the 12 o’clock and 6 o’clock positions and attempting to rock it back and forth. Excessive play or movement can suggest a worn or loose axle spindle, which can compromise the vehicle’s stability and handling.

If you observe any of these signs, it is recommended to have the axle spindle inspected by a qualified mechanic or technician who can assess the condition of the spindle and perform the necessary repairs or replacement.

In addition to visual inspection and observation of the mentioned signs, specialized diagnostic tools may be used to further evaluate the condition of the axle spindle. These tools can measure wheel alignment, detect excessive play or movement, and identify any abnormalities in the spindle assembly.

Regular maintenance and periodic inspections of the suspension system can help in identifying early signs of axle spindle wear or faults. It’s important to address any issues promptly to prevent further damage and ensure the optimal performance and safety of the vehicle.

In summary, common signs of a worn or faulty axle spindle include uneven tire wear, steering instability, pulling or drifting, unusual noises, and excessive play or movement in the wheel assembly. Careful observation, visual inspection, and professional evaluation can help identify these signs and determine the condition of the axle spindle.

editor by CX 2023-11-10

China Custom Widely Used Durable New Tractor Parts PTO Drive Shaft near me shop

Warranty: 1.5 a long time

Relevant Industries: Production Plant, OEM

Showroom Area: Italy

Video outgoing-inspection: Provided

Equipment Check Report: Provided

Marketing Type: New Item 2571

Kind: Shafts

Nearby Support Location: Italy

certificate: CE

Material: Metallic

Colour: Yellow&Black

Processing of yoke: Forging

Processing of tube: Cold drawn

Style: Tailored

Certification: CE Certificate

Right after Guarantee Service: Movie technical assistance

Regional Service Location: None

Packaging Particulars: Packing information:Iron pallet&wood carton®ular export packaging

Port: HangZhou or ZheJiang

Merchandise Info Merchandise Info PTO Shaft The energy take-off (PTO) is a advanced system, permitting implements to attract vitality from the motor and transmit it to one more software. It performs as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power get-off shaft (PTO shaft) is a critical component, made and manufactured for continuous heavy-responsibility use. A great PTO shaft ought to be robust sufficient to bear the torsion and shear anxiety and reduce vibration.

Setforge, Auto Equipment Auto Spare Parts Entrance Right Semi-axle Assembly Travel Shaft 43410-02640 For COROLLA ZRE120 2007-2017 the forging subsidiary of At any time-Electricity Team, manufactures chilly extruded PTO shafts for all varieties of agriculture autos. Our PTO shafts supply fantastic dependability and toughness in the course of every day use.

EP Group has been internationally identified as a reputable international provider. Our point out-of-the-artwork production approach and skilled engineers make certain the best-high quality of all Farinia components.

Right after Guarantee Services

Online video technological help

Relevant Industries

Producing Plant

Neighborhood Service Place

Italy

Showroom Spot

Italy

Warranty

1.5 many years

Kind

Shafts

Place of Origin

China

China

ZHangZhoug

Manufacturer Title

EPG

certification

CE

Substance

Steel

Coloration

Yellow&Black

Processing of yoke

Forging

Processing of tube

Chilly drawn

Design and style

Personalized

Certificate

CE Certificate

Product Display Solution Show PTO Travel Line Gen … PTO Generate Line Gen … Industrial-Duty Ro … CompanyInfo Company Profile At any time-Electricity Group EPG have higher-tech equipment and test equipment. We can make entire world course large precision merchandise. Certifications Certifications

Shipment & Payment Our Advantages A: Your inquiry related to our merchandise or prices will be replied in 24 hrs. B: Defense of your income area, Air Pressure 1 st Patrick Platform Reduced Reduce Working Footwear Skateboarding Sneaker mens Outdoor Sports activities Nike Trainers Sneakers suggestions of design and all your private data. C: Best top quality and competitive price tag. ……

faq FAQ 1) How can I spot purchase? A: You can make contact with us by e mail about your purchase details, or location order on line.

2) How can I pay out you? A: Soon after you confirm our PI, we will ask for you to spend. T/T (HSBC bank) and Paypal, Western Union are the most usual techniques we are utilizing.

……

Information to Travel Shafts and U-Joints

If you are concerned about the overall performance of your car’s driveshaft, you happen to be not on your own. Numerous auto proprietors are unaware of the warning indications of a unsuccessful driveshaft, but being aware of what to look for can aid you avoid pricey repairs. Right here is a brief guidebook on generate shafts, U-joints and maintenance intervals. Outlined beneath are important points to consider prior to changing a car driveshaft.

Signs and symptoms of Driveshaft Failure

Pinpointing a defective driveshaft is easy if you’ve at any time listened to a unusual sounds from under your vehicle. These seems are brought on by worn U-joints and bearings supporting the push shaft. When they fail, the drive shafts stop rotating appropriately, producing a clanking or squeaking audio. When this transpires, you could listen to sounds from the side of the steering wheel or ground.

In addition to sounds, a defective driveshaft can lead to your vehicle to swerve in tight corners. It can also direct to suspended bindings that limit all round management. As a result, you must have these symptoms checked by a mechanic as soon as you notice them. If you observe any of the symptoms over, your subsequent stage need to be to tow your vehicle to a mechanic. To stay away from additional difficulties, make certain you’ve taken precautions by checking your car’s oil level.

In addition to these signs, you must also seem for any sounds from the drive shaft. The first point to appear for is the squeak. This was triggered by severe harm to the U-joint attached to the generate shaft. In addition to noise, you should also search for rust on the bearing cap seals. In intense circumstances, your car can even shudder when accelerating.

Vibration while driving can be an early warning signal of a driveshaft failure. Vibration can be owing to worn bushings, caught sliding yokes, or even springs or bent yokes. Extreme torque can be brought on by a worn centre bearing or a damaged U-joint. The car may make abnormal noises in the chassis technique.

If you recognize these symptoms, it’s time to consider your auto to a mechanic. You must examine regularly, particularly heavy autos. If you’re not confident what is leading to the sounds, verify your car’s transmission, motor, and rear differential. If you suspect that a driveshaft needs to be replaced, a certified mechanic can replace the driveshaft in your car.

Push shaft variety

Driveshafts are utilized in many various types of automobiles. These consist of four-wheel push, entrance-engine rear-wheel drive, bikes and boats. Each variety of drive shaft has its possess purpose. Beneath is an overview of the 3 most frequent kinds of generate shafts:

The driveshaft is a circular, elongated shaft that transmits torque from the motor to the wheels. Drive shafts often incorporate many joints to compensate for adjustments in size or angle. Some push shafts also contain connecting shafts and interior continuous velocity joints. Some also incorporate torsional dampers, spline joints, and even prismatic joints. The most crucial issue about the driveshaft is that it performs a essential part in transmitting torque from the engine to the wheels.

The travel shaft needs to be the two light-weight and sturdy to transfer torque. Although metal is the most commonly used substance for automotive driveshafts, other materials this sort of as aluminum, composites, and carbon fiber are also commonly used. It all relies upon on the function and dimensions of the automobile. Precision Manufacturing is a very good supply for OEM products and OEM driveshafts. So when you happen to be searching for a new driveshaft, maintain these factors in thoughts when purchasing.

Cardan joints are another common generate shaft. A common joint, also recognized as a U-joint, is a versatile coupling that enables a single shaft to drive the other at an angle. This kind of push shaft makes it possible for energy to be transmitted even though the angle of the other shaft is consistently modifying. While a gimbal is a good choice, it is not a best resolution for all purposes.

CZPT, Inc. has state-of-the-artwork equipment to support all types of drive shafts, from little autos to race cars. They serve a assortment of demands, which includes racing, industry and agriculture. Whether or not you need a new drive shaft or a straightforward adjustment, the personnel at CZPT can fulfill all your needs. You are going to be again on the road soon!

U-joint

If your auto yoke or u-joint displays symptoms of dress in, it is time to change them. The best way to change them is to follow the actions underneath. Use a large flathead screwdriver to examination. If you feel any movement, the U-joint is faulty. Also, inspect the bearing caps for injury or rust. If you can not discover the u-joint wrench, consider examining with a flashlight.

When inspecting U-joints, make sure they are appropriately lubricated and lubricated. If the joint is dry or poorly lubricated, it can swiftly fail and cause your auto to squeak while driving. An additional indicator that a joint is about to fall short is a sudden, too much whine. Examine your u-joints each and every 12 months or so to make positive they are in appropriate working get.

Whether or not your u-joint is sealed or lubricated will rely on the make and design of your vehicle. When your vehicle is off-highway, you want to install lubricable U-joints for toughness and longevity. A new driveshaft or derailleur will price more than a U-joint. Also, if you never have a great understanding of how to change them, you could want to do some transmission perform on your automobile.

When replacing the U-joint on the drive shaft, be positive to select an OEM substitution whenever feasible. Even though you can effortlessly repair or substitute the unique head, if the u-joint is not lubricated, you might need to have to change it. A destroyed gimbal joint can cause difficulties with your car’s transmission or other critical elements. Changing your car’s U-joint early can make sure its long-phrase overall performance.

One more choice is to use two CV joints on the drive shaft. Making use of a number of CV joints on the travel shaft assists you in situations where alignment is difficult or running angles do not match. This kind of driveshaft joint is far more pricey and complex than a U-joint. The down sides of making use of numerous CV joints are added duration, fat, and lowered working angle. There are several reasons to use a U-joint on a push shaft.

maintenance interval